Shrinkage

Ever feel like your inventory is playing hide-and-seek with your profits?

That’s shrinkage — the silent, sneaky villain of the restaurant world. It’s what happens when your ingredients mysteriously vanish between delivery and sale, and it can bleed your business dry if you’re not watching closely.

The worst part? You usually don’t even see it happening. But your books feel it. Hard.

What Shrinkage Really Means

In simple terms, shrinkage = inventory loss. It’s the stuff you paid for but never got paid for. And there are three major culprits:

-

Theft – Yep, it happens. Whether it’s pilfered produce, liquor going “missing,” or unpaid meals for friends, internal theft is a real issue.

-

Waste – Overcooked steaks, spoiled veggies, or that giant pot of curry no one ordered — all of it adds up.

-

Admin Errors – Miscounted inventory, wrong portion sizes, or recipe deviations that throw your food cost math off track.

The Real Cost of “Just a Little” Shrinkage

Here’s the painful truth:

If you lose ₹100 worth of ingredients to shrinkage, you often need ₹300–₹500 in extra sales just to break even.

Ouch, right?

So shaving just 2–3% off shrinkage could be the easiest way to boost profits — without adding a single customer or upselling a single dessert.

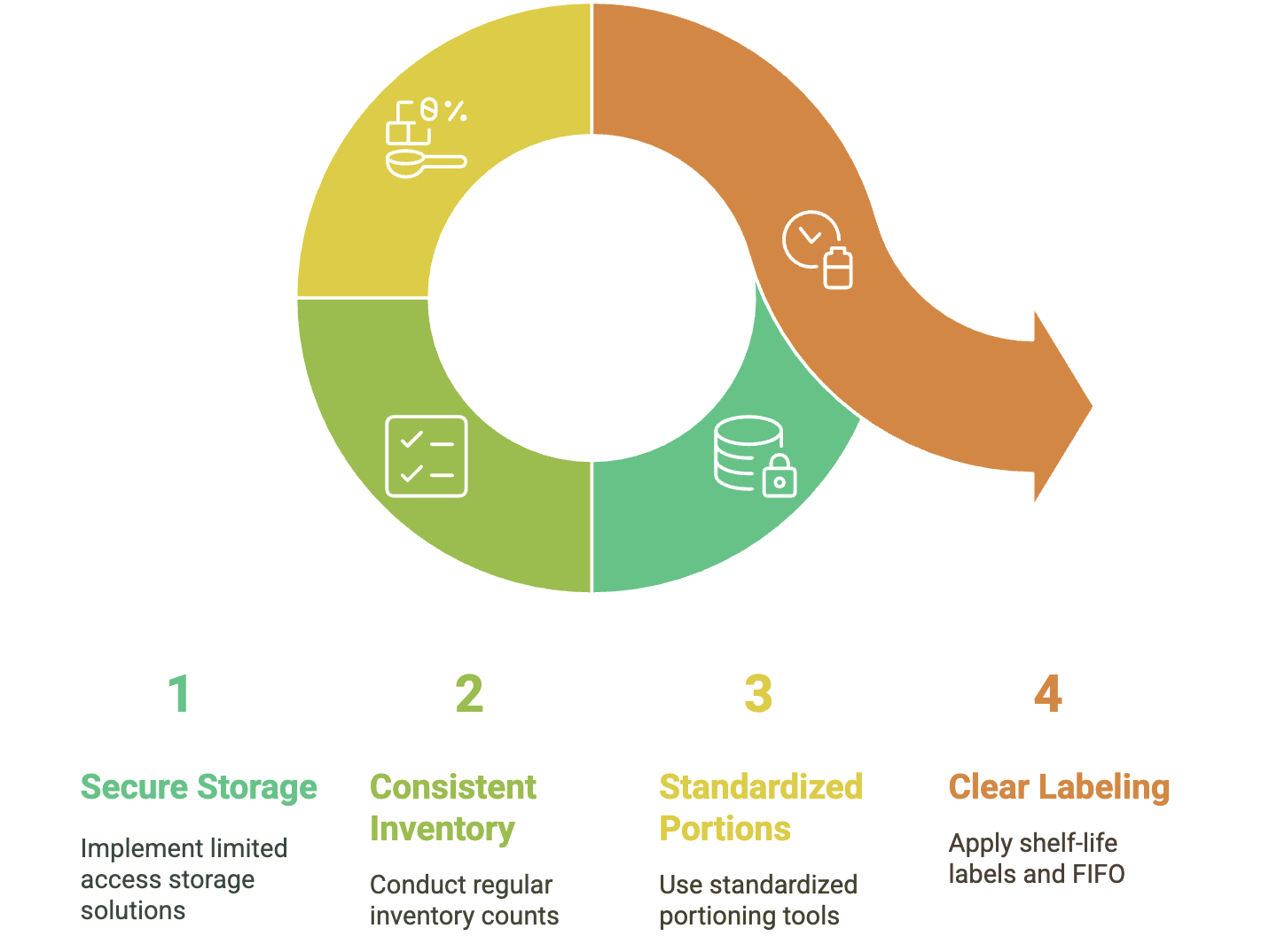

How to Stop the Leak (Without Driving Your Staff Crazy)

Tackling shrinkage isn’t about turning your kitchen into a surveillance zone. It’s about putting smart systems in place. Think:

-

Secure storage with limited access

-

Consistent inventory counts (weekly, not “when we remember”)

-

Standardized portions and prep processes

-

Clear shelf-life labeling and first-in-first-out systems

Better yet, ditch the spreadsheets.

Modern inventory software tracks usage patterns and sends alerts when something’s off — like if you’re suddenly going through way more cheese than usual. (Unless you’re running a pizza festival.)

Your Team is Your Best Defense

When your staff understands what shrinkage is really costing the business — and possibly their bonuses — they’ll start seeing waste differently.

-

Train your team on proper food handling and portioning.

-

Show them shrinkage stats openly.

-

Set goals, and maybe even reward them when those goals are met.

Because when your prep cooks and servers care about shrinkage, everyone wins.

Tech Tools That Do the Heavy Lifting

You don’t have to do it all manually anymore. Today’s tech can help you stay ahead of shrinkage:

-

Smart storage with temperature sensors (goodbye, spoilage!)

-

Digital scales and barcode scanners to monitor stock in real time

-

AI-based ordering systems that know exactly how much stock you need — not too little, not too much

It’s not just futuristic — it’s practical.

Make Shrinkage a Weekly Conversation, Not a Monthly Surprise

Set a rhythm. Do weekly audits. Compare your ideal food cost to the actual cost. Investigate variances right away — don’t let them slide.

Over time, you’ll spot patterns:

Maybe your evening shift consistently uses more meat. Or maybe that fancy olive oil just evaporates.

The earlier you spot it, the faster you stop it.

Final Thought?

Shrinkage will always exist — but how much it eats into your profits is totally in your hands.

Every rupee saved on shrinkage goes straight to your bottom line.

So if you want to run a leaner, more profitable restaurant?

Start by plugging the holes in your pantry.